CORE VALUES OF BLOCKCHAIN TRACK & TRACE

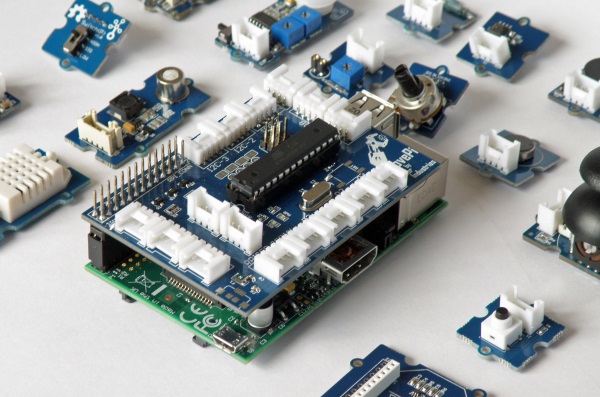

TNT is a unique Source-to-Market track and trace solution that uses IoT devices (BT, GPS, etc) to capture all events required throughout the objects history.

Our team of Engineers, Developers, Lean Six Sigma Black Belts, and IoT Designers will work with you to create a custom solution to deliver Strategic deployment of sensors and blockchain technologies. We assist in global business expansion in emerging markets. Strategic deployment strategies of sensors and blockchain technologies

Traceability and Inventory System Application with Blockchain Technology. Self-service Dispenser Integrations, Mobile App Development and User Interface Customization. Intelligent tamper resistant packaging.

Blockchain gateway for devices. IoT from Source to Sale. Farm & Source location based system. Integrated with industrial grade humidity and temperature monitoring.

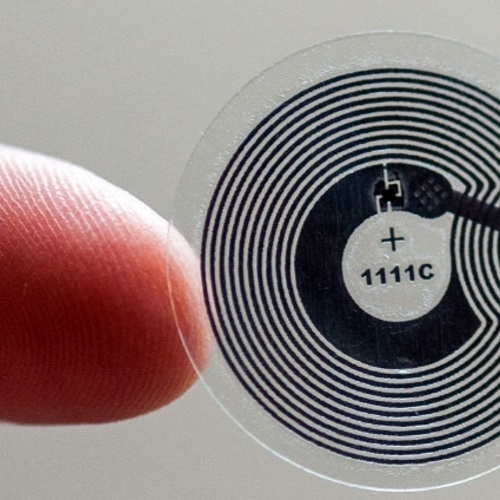

Tamper Resistant Packing RFID, NFC and UHF Tagging IoT Tags, IoT Readers, IoT Sensors and IoT Scanners

BLOCKCHAIN | SUPPLY CHAIN | INTERNET OF THINGS

What we deliver

Platform

We deliver a foundation for your custom-tailored IoT back-end system. Built as a cluster, the architecture eliminates the risk of downtime by enabling high availability.

Integration Options

REST interfaces (REpresentational State Transfer) with product-specific services, log appenders for integration with analytics, data management and visualization systems, pluggable implementations of custom transports, and other modules.

No Single point of failure

The platform is designed to handle millions of connected devices under peak pressure without ever getting tired.

Pre-Integrated

Oracle, Mongo DB, Cassandra and Hadoop are just a few of the pre-integrated data processing systems built into the platform.

Data

Collecting and analyzing data from connected devices is one of the most recurring IoT use cases. Our mission is to make these tasks totally straight forward, even at a massive scale.

Warehousing

The IoT platform serves as a foundation for your back-end system that you are free to expand and customize to meet the specific requirements of your logistical requirements.

IOT Gateways

We enable advanced IoT features for gateways and WIFI routers. We empower these devices to act as an affordable yet multi-functional bridge between endpoints and the cloud.

Personal Area Network (PAN)

We simplify data collection from basic sensors and devices that used PAN-based protocols such as Bluetooth, Zigbee, or Zwave for connectivity.

Robust and scalable

For massive amounts of real-time data or large-scale deployments, we allow inplementting the edge analytics into IoT gateways, which consolidates data to send to the cloud more efficiently.

Connectivity

Our platform is transport-agnostic. We support applications that function over any petty of network connection, either persistent or intermittent.

Pluggable protocols

Connection parameters are automatically advertised to endpoints and balance the load across the network.

Multi-channel support

Flexible assignment of transport implementations to platform services. Notifications may be delivered to endpoints via UDP or SMS while configuration and profile data may be synced via an AES-encrypted TCP protocol.

Hardware

We enable data management for connected objects and your back-end infrastructure by providing the server and endpoint SDK components. The SDKs get embedded into your connected device and implement real-time bi-directional data exchange with the platform.

IoT Devices made simple

Our SDKs are capable of being integrated with virtually any type of connected device or microchip providing a straightforward hardware integration procedure.

Hardware-agnostic

You can integrate pretty much any device, starting from those powered by fully-functional operating systems, all the way down to resource-constrained micro-controllers with less than 10KB of available RAM

What you can do

Agriculture

Agri-supply chains are economic systems which distribute benefits and apportion risks among participants. Thus, supply chains enforce internal mechanisms and develop chain wide incentives for assuring the timely performance of production and delivery commitments. They are linked and interconnected by virtue of shared information and reciprocal scheduling, product quality assurances and transaction volume commitments. Process linkages add value to agricultural products and require individual participants to co-ordinate their activities as a continuous improvement process. Costs incurred in one link in the chain are determined in significant measure by actions taken or not taken at other links in the chain. Extensive pre-planning and co-ordination are required up and down the entire chain to affect key control processes such as forecasting, purchase scheduling, production and processing programming, sales promotion, and new market and product launches.